| Construction condition | |

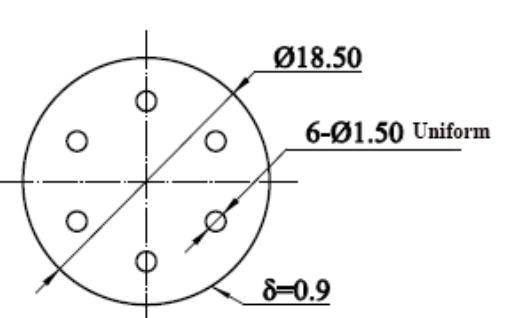

| Diaphragm material | SS 316L |

| Housing material | SS 316L |

| Pin Wire | Gold-plated karaf /100mm silicone rubber wire |

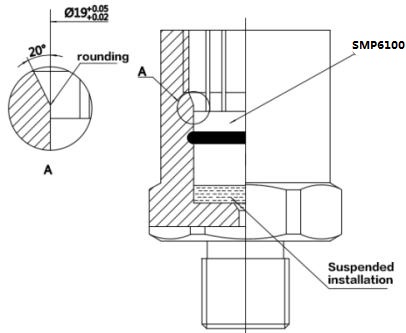

| Back pressure tube | SS 316L (gauge and negative pressure only) |

| Seal ring | Nitrile rubber |

| Electrical Condition | |

| Power supply | ≤2.0 mA |

| Impedance input | 3kΩ-6 kΩ |

| Impedance output | 3kΩ-6 kΩ |

| Response | (10%~90%):<1ms |

| Insulation resistance | 100MΩ,100V DC |

| Overpressure | 2times FS, ( 0C/0B/0A/02 5times FS) |

| Environmental Condition | |

| Media applicability | Fluid which has no corrosion on stainless steel and nitrile rubber |

| Shock | No change at 10gRMS,(20~2000)Hz |

| Impact | 100g,11ms |

| Position effects | Deviate 90° from any direction, zero change≤±0.05%FS |

| Basic Condition | |

| Environment temperature | (25±1)℃ |

| Humidity | (50%±10%)RH |

| Atmospheric pressure | (86~106) kPa |

| Power supply | (1.5±0.0015)mA DC |

| All tests are in accordance with relevant national standards, including GB / T2423-2008, GB / T8170-2008, GJB150.17A-2009, etc., and also comply with the Company's "Pressure Sensor Enterprise Standards" provisions of the relevant content. | |

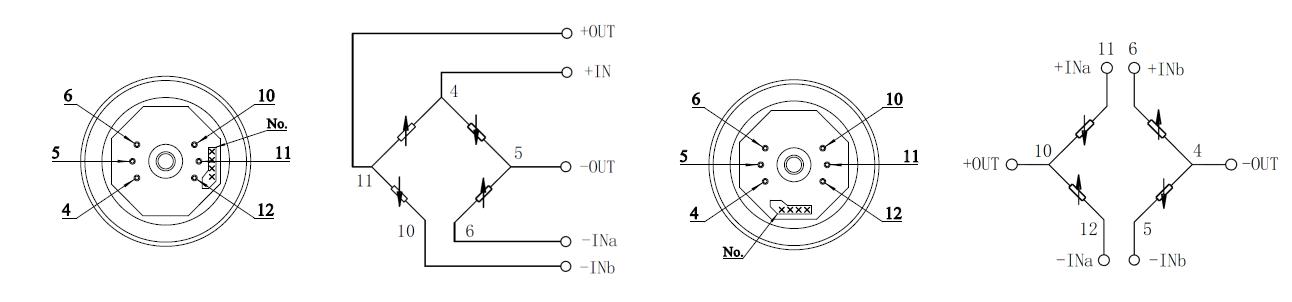

●Electrical connection

●Electrical connection

| Item | Min. | Typ. | Max. | Units |

|

Linearity |

±0.1 | ±0.2 | %FS,BFSL | |

| Repeatability | ±0.05 | ±0.075 | %FS | |

| Hysteresis | ±0.05 | ±0.075 | %FS | |

| Zero output | ±2.0 | mV DC | ||

| FS output | 45 | 130 | mV DC | |

| Compensated temp. range | -10~80 ( 0A/0B/0C 0~70) | ℃ | ||

| Working temp. range | -40~125 | ℃ | ||

| Storage temp. range | -55~150 | ℃ | ||

| Zero temp. error | ±0.75 | ±1.0 | %FS, @25℃ | |

| Full temp. error | ±0.75 | ±1.0 | %FS, @ 25℃ | |

| Long term stability error | ±0.1 | %FS/year | ||

|

Note:1. The above performance indicators are tested under the benchmark conditions 2. The temperature range for temperature drift test is the compensation temperature range |

||||

| CSMP6100 | High stable piezo-resistive OEM sensor | |||||

| Range code | Measurement range | Pressure type | Range code | Measurement range | Pressure type | |

| 0C | 0~10kPa | G | 12 | 0~2MPa | G/A | |

| 0B | 0~20kPa | G | 13 | 0~3.5MPa | G/A | |

| 0A | 0~35kPa | G | 14 | 0~7MPa | A/S | |

| 02 | 0~70kPa | G | 15 | 0~15MPa | A/S | |

| 03 | 0~100kPa | G/A | 17 | 0~20MPa | A/S | |

| 07 | 0~200kPa | G/A | 18 | 0~35MPa | A/S | |

| 08 | 0~350kPa | G/A | 19 | 0~70MPa | A/S | |

| 09 | 0~700kPa | G/A | 20 | 0~100MPa | A/S | |

| 10 | 0~1MPa | G/A | ||||

| Code | Pressure Type | |||||

| G | Gauge pressure | |||||

| A | Absolute pressure | |||||

| S | Sealed gauge pressure | |||||

| Code | Electrical connection | |||||

| 1 | Gold-plated kovar pin | |||||

| 2 | 100mm Silicone rubber leads | |||||

| Code | Special measurement | |||||

| Y | Gauge pressure type can be used to measure negative pressure Note① | |||||

| CSMP6100-0B-G-1-Y the whole spec | ||||||